FrontRow Strengthens Board with Strategic CEO Appointment

01 - 11 - 2024

FrontRow Energy Technology Group has appointed Steve Kent to the position of CEO in a …

FrontRow Strengthens Board with Strategic CEO Appointment30 - 06 - 2017

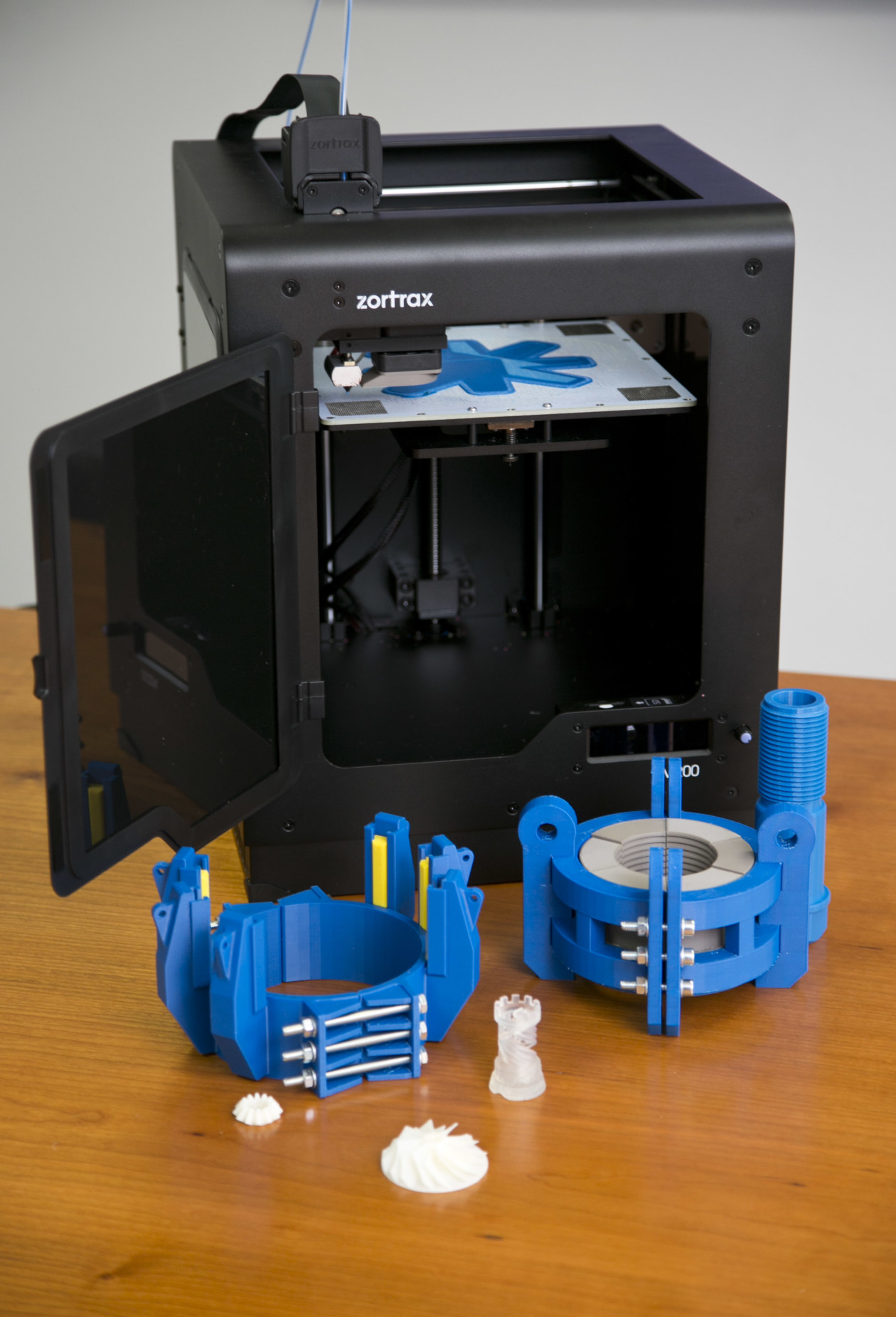

“Created in the depths of the recent downturn, FrontRow Energy Technology Group (FrontRow) views technology as a key enabler of cost reduction in the oil industry. One trend is of particular interest to FrontRow: 3D-printing.

“Whether making small plastic models or producing high-strength alloy parts, 3D-printing is already transforming the creation, development, marketing and production of new products. For even the smallest companies, 3D-printers enable the conversion of ideas into functional prototypes at a cost and speed that would have been unthinkable ten years ago. One FrontRow company, Well-Sense Technology, used 3D-printing extensively to develop its fibre-line intervention (FLI) technology; a method for disposable optical sensing. From the initial FLI concept to the first test of a working prototype in a well took only a few months, with many design iterations along the way.

“3D-printing also allows shapes to be created that are difficult, if not impossible, to make using conventional machining. Furthermore, complexity tends to reduce cost in printed parts, as the cost depends only upon the volume of material used, rather than the material that is removed and wasted. FrontRow is already using printing of high-nickel alloys for ultra-compact well intervention tools. Within a few years, the oil industry can expect to see very large printed structures being used as a matter of routine.”

View the full article here: http://www.oedigital.com/techn...